A pilot study to assess a risk of a high-risk group of low back pain membership in workers who perform the manual material handling tasks

Article information

Abstract

Background

We conducted this experimental study to estimate a risk of a high-risk group of low back pain (LBP) membership in workers who perform the manual material handling (MMH) tasks in an actual workplace setting.

Methods

The subjects include healthy workers who were engaged in 12 MMH tasks at 6 manufacturing companies. We assessed the dynamic motion of trunk or lumbar spine using an industrial lumbar motion monitor (BioDynamics Laboratory of Ohio State University). The subjects were evaluated for the age, gender, years of working and anthropometric measurements (e.g., height, weight, shoulder height, elbow height, iliac height, leg length, trunk length, trunk circumference, iliac width, iliac depth, xiphoid width and xiphoid depth). Moreover, they were also evaluated for a risk of a high-risk group of LBP membership based on lift frequency, average twisting velocity, maximum moment, maximum sagittal flexion and maximum lateral velocity.

Results

The subjects who were engaged in a packaging at a detergent manufacturing company are at the greatest risk of LBP (63.76%). This was followed by packaging at a leather product manufacturing company (57.06%), packaging at a non-metallic casting material manufacturing company (57.03%), manual injection at a non-metallic casting material manufacturing company (52.00%), toggling at a leather product manufacturing company (46.09%), non-metallic casting material manufacturing company (42.88%), rolling at a non-metallic mineral product manufacturing company (42.12%), shooting at a non-metallic casting material manufacturing company (40.99%), vacuum processes at a leather product manufacturing company (35.00%), looping at a general industrial machinery manufacturing company (33.93%), setting at a leather product manufacturing company (30.22%) and packaging at a general metal product manufacturing company (22.02%).

Conclusions

Our approach indicates that there is a risk of a high-risk group of LBP membership in workers who perform the MMH tasks.

BACKGROUND

Low back pain (LBP) is such a common problem as to affect ≥ 25% of total adult workers.1 Its symptoms may be worsened by physical demands of the work.2 Nevertheless, both work- and non-work-related episodes of LBP may also cause work absences. This may lead to problems that workers can perform normal job tasks.3 LBP in a workplace should be considered medically serious; it may cause occupational challenges and disruption because it is self-limiting in nature.4

Workers may be vulnerable to both acute and chronic episodes (> 6 months) of LBP irrespective of whether they are men or women.5 Workers presenting with primary chronic LBP should be meticulously examined, followed by appropriate treatments, employer coordination or occupational rehabilitation.67

Workers across all industries and occupations may be vulnerable to LBP, but physical demands of the work raise a risk of developing it.8 From this context, unnatural body positions, a sudden change in the task, fatigue, heavy lifting, outdoor work, hand movements and frequent bending and twisting may serve as risk factors of LBP.91011 Moreover, psychological demands of the work, such as low supervisor support, stressful monotonous work, a rapidly paced work environment, job insecurity, work-family imbalance and exposure to hostile work, may also serve as risk factors of LBP.91011

In 1990, Straker12 defined the manual material handling (MMH) as any activities that are in need of force generated by a person to lift, lower, push, pull, carry or otherwise move, hold or restrain a person, animal or thing. Moreover, the Occupational Safety and Health Administration defined the MMH as the act of moving materials by hand to lift, lower, push, pull and carry them.13 According to a systematic review of the previous studies conducted by Kuiper et al.,14 of various MMH tasks, lifting and lowering are the most frequently involved in diverse occupations and pose a major risk to workers' health status. The MMH tasks are commonly seen in blue collar jobs, such as manufacturing, building and construction, mechanical work, maintenance, repair or technical installations.15 Moreover, they are also seen in healthcare professionals, such as nurses, surgeons, dentists and physiotherapists.16 All the workers mentioned herein are vulnerable to LBP.17 According to a survey conducted by Ferguson et al.18 in MMH workers, a 1-year prevalence of LBP for those whose symptoms last for ≥ 7 days, those requiring medical treatments and those requiring a leave from work was 25%, 14% and 10%, respectively.

Given the above background, we conducted this experimental study to estimate a risk of a high-risk group of LBP membership in workers who perform the MMH tasks in an actual workplace setting.

METHODS

Study setting and subjects

The current study was conducted in healthy workers who were engaged in 12 MMH tasks at 6 manufacturing companies. We included normal healthy men or women who were engaged in MMH tasks at 6 manufacturing companies, the subjects who could be assessed for the dynamic motion and postures of the trunk or lumbar spine and heavy object handling processes and those who could be assessed for the type and details of MMH tasks and anthropometric characteristics. But we excluded the subjects who had an inability to comply with the study protocol.

The current study was conducted in compliance with the relevant ethics guidelines following the approval by the Institutional Review Board (IRB) of Dongguk University Gyeongju Hospital (IRB No.110757-202109-HR-02-02). All procedures described herein were performed in accordance with the 1964 Declaration of Helsinki and its later amendments or comparable ethical standards. The subjects submitted a written informed consent for study participation.

Experimental protocol

We assessed the dynamic motion of trunk or lumbar spine using an industrial lumbar motion monitor (LMM; BioDynamics Laboratory of Ohio State University, Columbus, OH, USA), as previously described.1920

The LMM was designed to document 3-dimensional (3D) components of the trunk motion in the work environment. It was modeled after the trunk motion control system of the back. That is, the spine is guided by the spinous and transverse processes that form a T-section in the posterior aspects of each spinal vertebra. T-sections are connected to each other with ligaments and muscles that envelop the facet joints of the spinal segments. The LMM is an exoskeleton of the spine that replicates the motion of these T-sections in the lumbar spine. Thus, T-sections of the LMM are intended to simulate the motion of the facet joints. The LMM is worn on the back of the worker and moves along with the worker. Each edge of the T-section is connected to 3 potentiometers on the base of the LMM via wires. The wires differentially change the voltage readings in the potentiometers as the LMM moves forwards, backwards or to the sides. A cable is also placed through the junction in each T-section and then connected to a fourth potentiometer that changes as the LMM is twisted. Thus, the LMM measures the difference in spine position of the lumbar spine (as a unit) relative to the pelvis.21

The potentiometer signals are interfaced with an analog-to-digital converter and the signals are recorded on a microcomputer. The signals have been calibrated to correlate with trunk angle. The signals are then processed to determine the position, velocity and acceleration of the trunk as a function of time.21

To quantify the magnitude of angle, the angular velocity and acceleration, the duration of exposure to the risk of developing LBP depending on the direction of lumbar motion and the degree of such risk based on a model for estimating it, we analyzed the LMM data. We also analyzed the LMM data relative to the level of risk of developing LBP, thus attempting to determine whether the subjects could perform an excessive motion of the trunk or lumbar spine in an actual workplace setting; these include lifting strength ratio, average twisting velocity, maximum moment, maximum sagittal flexion and maximum lateral velocity.22

A risk of a high-risk group of LBP membership was calculated using a low-back disorder risk assessment model, as previously described by Marras et al.222324

Criteria for analyzing the experimental data

The subjects were evaluated for the age, gender, years of working and anthropometric measurements (e.g., height, weight, shoulder height, elbow height, iliac height [left and right], leg length [upper and lower], trunk length, trunk circumference, iliac width, iliac depth, xiphoid width and xiphoid depth). Moreover, they were also evaluated for a risk of a high-risk group of LBP membership based on lift frequency, average twisting velocity, maximum moment, maximum sagittal flexion and maximum lateral velocity, whose definitions have been described elsewhere.2526

All data was expressed as mean ± standard deviation or the number of the subjects with percentage, where appropriate.

RESULTS

Baseline characteristics of the subjects

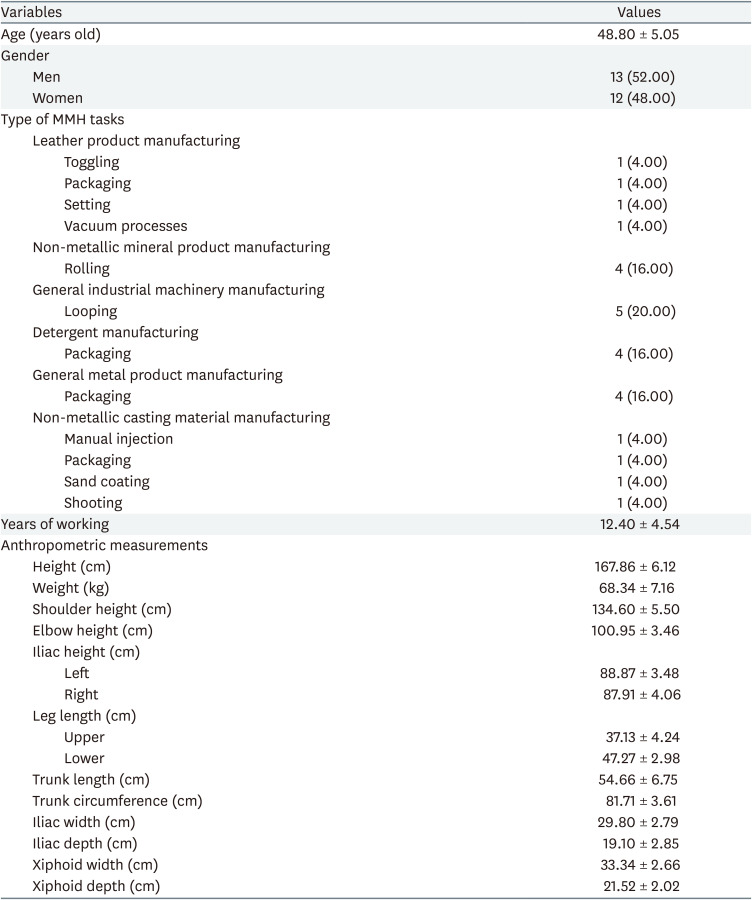

The current study enrolled a total of 25 subjects (n = 25), comprising 13 men (52.00%) and 12 women (48.00%), whose mean age was 48.80 ± 5.05 years old. Moreover, they were engaged in their work during a mean period of 12.40 ± 4.54 years. Furthermore, their anthropometric measurements were also measured and then averaged; these include height (167.86 ± 6.12 cm), weight (68.34 ± 7.16 kg), shoulder height (134.60 ± 5.50 cm), elbow height (100.95 ± 3.46 cm), Iliac height (left: 88.87 ± 3.48 cm and right: 87.91 ± 4.06 cm), leg length (upper: 37.13 ± 4.24 cm and lower: 47.27 ± 2.98 cm), trunk length (54.66 ± 6.75 cm), trunk circumference (81.71 ± 3.61 cm), iliac width (29.80 ± 2.79 cm), iliac depth (19.10 ± 2.85 cm), xiphoid width (33.34 ± 2.66 cm) and xiphoid depth (21.52 ± 2.02 cm). Baseline characteristics of the subjects are represented in Table 1.

Estimation of a risk of a high-risk group of LBP membership using an LMM

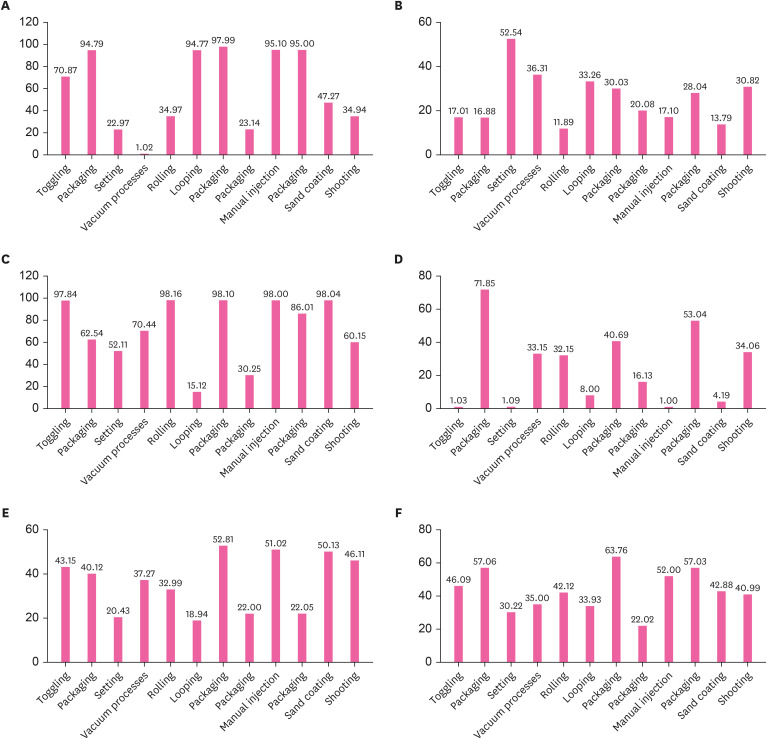

As shown in Fig. 1A-E, lift frequency was the highest (97.99) in workers who were involved in packaging in the detergent manufacturing industry; average twisting velocity was the highest (52.54) in those who were involved in setting in the leather product manufacturing industry; maximum moment was the highest (98.10) in those who were involved in packaging in the detergent manufacturing industry; maximum sagittal flexion was the highest (71.85) in those who were involved in packaging in the leather product manufacturing industry; and maximum lateral velocity was the highest (52.81) in workers who were involved in packaging in the detergent manufacturing industry.

Estimation of a risk of a high-risk group of LBP membership. (A) Lift frequency was the highest (97.99) in workers who were involved in packaging in the detergent manufacturing industry; (B) average twisting velocity was the highest (52.54) in those who were involved in setting in the leather product manufacturing industry; (C) maximum moment was the highest (98.10) in those who were involved in packaging in the detergent manufacturing industry; (D) maximum sagittal flexion was the highest (71.85) in those who were involved in packaging in the leather product manufacturing industry; and (E) maximum lateral velocity was the highest (52.81) in workers who were involved in packaging in the detergent manufacturing industry. (F) The subjects who were engaged in a packaging at a detergent manufacturing company are at the greatest risk of LBP (63.76%).

LBP: low back pain.

As shown in Fig. 1F, the subjects who were engaged in a packaging at a detergent manufacturing company are at the greatest risk of LBP (63.76%). This was followed by packaging at a leather product manufacturing company (57.06%), packaging at a non-metallic casting material manufacturing company (57.03%), manual injection at a non-metallic casting material manufacturing company (52.00%), toggling at a leather product manufacturing company (46.09%), non-metallic casting material manufacturing company (42.88%), rolling at a non-metallic mineral product manufacturing company (42.12%), shooting at a non-metallic casting material manufacturing company (40.99%), vacuum processes at a leather product manufacturing company (35.00%), looping at a general industrial machinery manufacturing company (33.93%), setting at a leather product manufacturing company (30.22%) and packaging at a general metal product manufacturing company (22.02%).

DISCUSSION

With the technological advancements in the modern industry, human life has become convenient.27 It is characterized by frequent use of machines for moving materials, although MMH tasks are still performed by workers.28 This may cause serious problems to workers. The MMH tasks are performed in a limited space, where workers' activity is highly dependent on their physical strength.29 In this regard, the ergonomic MMH tasks are justified. Otherwise, workers may be vulnerable to industrial accident involving damages to their body.30

It is worthwhile to incorporate ergonomic principles into the industrial work environment, which is essential for controlling the occurrence of musculoskeletal injuries (e.g., LBP). Positive effects of ergonomic interventions based on risk assessment tools and techniques have been well described in the literature.3132 Such interventions include lowering the prevalence and cost of injuries, reducing discomfort and fatigue and improving the productivity. But there are also contradictory reports that ergonomic interventions are not beneficial strategies in the context of work-related musculoskeletal disorders.3334 It would therefore be mandatory to assess a risk of a high-risk group of LBP membership in workers who perform the MMH tasks.

To date, several tools for risk assessment for LBP have been described in the literature.3536 They are based on the possible mechanisms underlying the onset of LBP in a workplace setting. Marras et al.36 assesed jobs using both the 1981 and 1991 National Institute for Occupational Safety & Health (NIOSH) lifting indices as compared with psychophysical limits. Moreover, Waters et al.37 assessed the feasibility of these tools, a 3D Static Strength Prediction Program, a program to predict the energy expenditure, and the use of heart rate and oxygen consumption. Furthermore, Lavender et al.38 reported that there would be no need to measure the same dimensions of the risk of LBP following a comparison of tools for assessment of the risk of it. It would therefore be mandatory to validate tools for assessment of the risk of LBP in a workplace setting. This should be accompanied by the optimization of the design of the workplace.

The importance of the feasibility of tools for assessment of the risk of LBP deserves special attention. There is no time to achieve make ergonomic improvements through trial and error in the current competitive market. This is not only because valuable resources are wasted on ineffective tools but also because the onset of LBP cannot be controlled in a timely manner. Consequently, the number of workers presenting with symptoms of LBP as well as the cost of damage would be increased and a loss of competitiveness would be hard to avoid. It is therefore imperative that effective tools for assessment of the risk of LBP in association with the design of a workplace, which will be essential for responding to a question regarding to the degree of the exposure of a workplace to such risk. From this context, an ergonomic model for assessing the risk of LBP has been developed using the LMM data and it has applied to diverse types of the MMH tasks.22243940 Based on these previous published studies, we estimated a risk of a high-risk group of LBP membership in workers who perform the MMH tasks in an actual workplace setting.

Despite rigorous examination and appropriate management, there may be a variability in an ability to stay at work or return to work in workers with LBP.341 Moreover, there is often discrepancy between workers' functional capacity and workability and their return-to-work outcomes.4243 Presumably, this might be because compound factors are involved in functional and occupational outcomes of workers with LBP; these include pain beliefs, healthcare systems, workplace support and accommodation and socio-demographics.44 It can therefore be inferred that characteristics of a worker, system and a workplace rather than the severity of LBP are determinants of the level of workability.

The onset or worsening of LBP can be prevented by decreasing high physical demands, avoiding unnatural body positions, educating workers for safe MMH tasks and re-engineering workstations and assembly lines.4546 This was well illustrated in a significant decrease in the occurrence of work-related LBP.46 According to randomized clinical trials, however, some recommendations for the prevention of LBP, such as use of a back belt, were found to be ineffective.4748 Therefore, workers with LBP should be given reasonable accommodation and support. Then, the relevant regulations and policies should be implemented to prevent long-term work disability, unemployment or unnecessary departures from the workforce.

Our results cannot be generalized not only because we evaluated only a small number of the subjects but also because we failed to serve a control group in predicting a risk of a high-risk group of LBP membership. This deserves further controlled studies to assess the feasibility of our approach. Moreover, limitations of the current study are that we failed to assess the feasibility of an industrial LMM as compared with other assessment tools. For MMH tasks, Lavender et al.38 reported that if properly used, currently-available assessment tools would be helpful for improving effects of ergonomic interventions in lowering or predicting a risk of work-related musculoskeletal disorders, including LBP. Such tools include the 1991 NIOSH lifting equation (NLE; NIOSH, Washington, D.C., USA), the University of Michigan 3D Static Strength Prediction Program (3D SSPP; University of Michigan, Ann Arbor, MI, USA), and the LMM. An appropriate use of such quantitative assessment tools is a more time-sensitive method for efficiently reducing the level of work-related biomechanical stress that may arise from ergonomics interventions.49 Further prospective controlled studies are therefore warranted to propose a model for predicting a risk of a high-risk group of LBD membership in workers who are involved in MMH tasks.

CONCLUSIONS

In conclusion, our approach indicates that there is a risk of a high-risk group of LBP membership in workers who perform the MMH tasks. But further prospective, randomized controlled studies are warranted to validate our approach.

Notes

Competing interests: The authors declare that they have no competing interests.

Author contributions:

Conceptualization: Lee S, Lee JY.

Data curation: Lee S, Heo S.

Writing - original draft: Lee S, Heo S.

Writing - review & editing: Lee S, Lee JY.

Abbreviations

LBP

low back pain

LMM

lumbar motion monitor

MMH

manual material handling

NIOSH

National Institute for Occupational Safety & Health

3D

3-dimensional